telephone:+86 13583612769

telephone:+86 13583612769

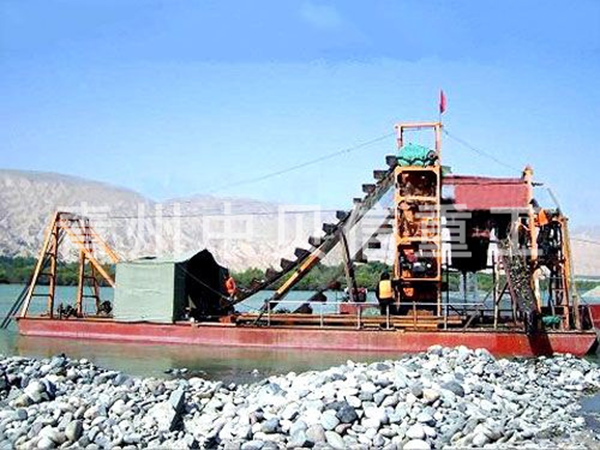

Principles and operating procedures of gold rush ships

2021-7-23

2021-7-23

Principles and operating procedures of gold rush ships

With the soaring gold price in recent years, the gold rush has arisen again. The sales of gold rush vessels and other gold rush equipment have promoted the progress of technology. The net selection rate of gold rush has increased from about 30% to more than 90%, increasing the input-output ratio. Advanced equipment, higher efficiency, and further stimulated the gold rush, become a hot investment.

Gold rush equipment in many forms, each has its own advantages and advantages, generally speaking, under the erosion of the current, the river sand in the river gold content is higher than the content of dry land river sand, will now be complex gold rush equipment - the principle of gold rush ship and operation procedures are introduced as follows:

Equipment composition:

As the name suggests, the gold rush ship is to move the gold system to the ship, added the river sand mining system, on the surface of the water to form a mobile integrated river sand concentrator. This equipment is composed of floating body, mining system, screening system, gold panning system, tailings discharge system, power system, water supply system, etc.

Equipment principle:

First of all, the excavation system will be the river sand from the underwater riverbed dug out of the water, and then into the screening system for screening, more than 10mm of stones into the tailings groove, from the tailings discharge system to the place far away from the gold rush ship, to ensure that the gold rush ship is not silted up, can continue to work. The material less than 10mm enters the gold panning system from the diversion trough for sand separation. According to the difference between the specific gravity of sand and gold, the gold with greater weight is settled at the bottom of the pulp, while the sand with smaller specific gravity floats on the upper layer of the pulp and is discharged to the tailings discharge system with water flow.

1. The floating body. The floating body is generally made of split form, two sides of the buoyancy box, a certain distance between the middle, not only increases the stability of the gold rush ship, but also facilitates the disassembly and transportation of equipment. The length of the floating body is designed according to the depth of the dredging sand. The greater the depth of the dredging sand, the longer the floating body. The width of the floating body is designed according to the working weight of the equipment. Generally speaking, the larger the workload, the wider the floating body.

2. Mining system. The mining system of the gold ship is composed of sand-dredging bucket and chain bucket digging type, shooting suction pipe and sand pump composed of shooting suction type, blade and sand pump composed of cutter suction type and other mining forms, according to many years of installation experience, because of the large percentage of sand, chain bucket mining form is better than the shooting suction type and cutter suction type.

3. Screening system. There are many forms of screening system. If there are more stones in the raw ore, the effect of roller screening is good. If there are fewer stones, the flat screen can be used.

4. Gold panning system. Gold system have fixed in the form of gold felt chute, encouraging type gold chute, automatic washing machine: gold centrifuge, spiral chute and shaking table, mercury gold plate, etc., the current application is more encouraging type gold chute and automatic washing machine with gold water set of centrifuge form, these two forms of simple structure, small volume, easy to move, large quantity, High degree of automation, high enrichment ratio (1000:1), the net concentration rate reached more than 90%, is the current gold rush ship and dry land gold panning equipment better choice.

5. Tailings discharge system: tailings discharge system has sand pumping pump type, chute type, conveyor belt type, etc., the commonly used form is chute type, no power, convenient maintenance, cost saving.

6. Power system. Due to the high level of automation requirements of gold rush ships, electric motors become the power of gold rush ships, there is no electricity set up river, can be equipped with diesel generator sets.

7. Water supply. The appropriate concentration of pulp for gold panning operations is around 30%, and the water supply system needs to continuously supply twice as much working water as it can handle.

Gold there is a lot of equipment completed in backfilling materials from mining to choose gold to discharge system, such as hoisting system, used for sand-excavating arm landing, ground anchor system, used in gold mining ship operation fixed, lighting systems, lighting, propeller for night operation, provide gold craft of self-propelled water, etc., is a tautology.

Operating rules:

1. Start the gold panning system, screening system and water supply system first, and then start the sand dredging part. When the whole machine runs normally, then put the bucket arm. When the machine is shut down, the bucket arm should be lifted first, and the sand and stone in the bucket are poured out, and then the mining system is stopped first, and then the screening system is stopped, which is the gold panning system, the water supply system, the tailings discharge system, the power system and the total power supply.

2. When magnifying the arm, start the hoist, so that the arm is slowly lowered, and check the situation in the bucket at the same time. The sand in the bucket is full and can be suspended below. In this way, the upper arm is placed in the lower limit -- the small Angle of the upper arm is suitable for 45° to the horizontal plane, but the mud layer is encountered when the upper arm is not placed in this position, and the lower arm can be stopped.

3. Make the ship forward, check the bucket is not satisfied, start the windbreaker, so that it slowly walk forward, the distance depends on the bucket sand, sand can continue to move forward when little, until full dig. When moving forward, the windlass on both sides should be alternated to make the equipment do a "zigzag" movement to increase the width of the operation.

4. If the underwater collapse machine has a sense of difficulty and pull should immediately loosen the windcutter to make its own back until pulling.

5. When the machine is working, it should often check whether there is any debris in the dredging bucket, such as large stones, mud blocks, etc. Once found, it should be cleaned up immediately so as not to cause damage or blockage of the funnel into the sieve.

6. Conveyor belt adjustment; Which side the belt is inclined to, you can tighten the screw on which side at any time until it is adjusted.

7. Equipment maintenance or filling of lubricating oil should be carried out when all the equipment is shut down.

8. In the rainy season, the equipment should be transferred to the river for a long time to stop, and the anchor should be placed well. If there is a fixed pile on the shore, the equipment can be fixed on the pile with the wire rope to prevent the flood from washing away the equipment.

9. The mechanical operator should be trained to work, the age should not be more than 55 years old, wear tight sleeves work clothes, wear safety helmet.

10. It is strictly prohibited to operate the machine after drinking!

current position

-

current position

-

3

consulting

3

consulting

+86 13583612769

+86 13583612769

top

top